Adr : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone : +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371-26630769

Comparison of the production process of potato and sweet potato starch making machine and the processing process of cassava starch production line machines

Potatoes, sweet potatoes, and cassava are all tuber root species. The production process of tuber starch includes cleaning raw materials, physical crushing, fiber separation, potato starch extraction, protein separation, refined starch, and dehydration and drying. After this series of machine processing, starch is produced.

Machines required in the production process of potato, sweet potato and cassava starch:

Dry screen-cleaning machine-segmentation machine-file grinder-centrifugal screen-sand remover-cyclone-vacuum dehydrator-airflow dryer-packaging machine

The production process of potato and sweet potato starch is almost the same. Potatoes are generally crushed by file grinders, and sweet potatoes can be crushed by file grinders or crushers and grinders. Compared with the production process of cassava starch, cassava is in long strips, so it needs to be pre-treated and added with a segmentation machine before crushing. It is easier to cut the cassava into small segments by the segmentation machine, and then crush it.

The following is the process of processing potato, sweet potato and cassava starch

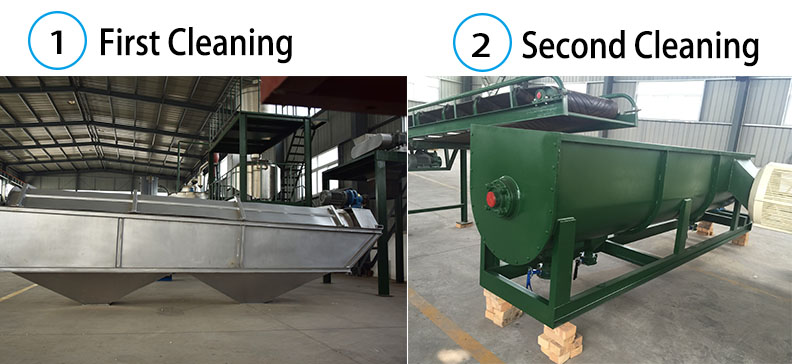

Cleaning raw materials

The cleaning process needs to be done by using a cleaning machine. Sweet potatoes, potatoes and cassava can both use dry screens and cage cleaning machines. The main purpose is to remove sand, dirt and skin from the surface of potatoes.

Crushing

The crushing of raw materials, according to the different characteristics of potatoes, sweet potatoes and cassava, potatoes are crushed by a file grinder, and sweet potatoes and cassava can be crushed by a file grinder or a crusher plus a crusher. Due to the size of potatoes, it is more appropriate to use a file grinder.

Starch slurry separation

The crushed material passes through a horizontal centrifugal screen or a vertical centrifugal screen to separate the starch slurry and slag through centrifugal force and gravity, and the starch particles and slag are separated. After that, the starch slurry enters the desander, and the sand is removed and collected in the desander container for discharge.

Purification and concentration

The starch slurry enters the cyclone group. The cyclone is a starch processing machine with three functions: washing, refining and recycling. The original starch milk is first washed in the first two washing cyclones, then refined in the refining cyclone, and finally covered in the last three recovery cyclones. After this process, the starch slurry turns white.

Vacuum dehydration

The starch dehydration machine often uses a vacuum dehydrator. This starch processing machine can effectively dehydrate the wet starch milk to a moisture content of about 38%~40%.

Starch dryer

After the starch milk is dehydrated with a vacuum dehydrator, the starch cake is transported to the inlet of the airflow dryer. After drying with the airflow dryer, the potato starch cake will be dried to about 13% moisture, and then the starch screen can be used to screen the dried starch to further improve the fineness of the potato starch.

The starch packaging machine packages the produced potato starch into 25-50 kg/bag, and the entire starch production process is completed.

All rights reserved:Kaifeng Sida Agricultural Products Equipment Co.,L SitemapSitemappSitemapsupport:dian zi