Adr : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone : +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371-26630769

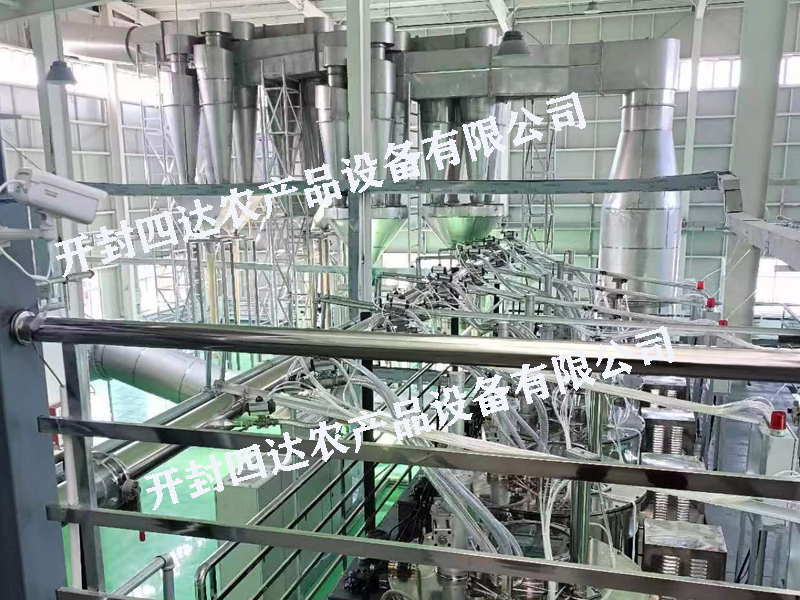

Wheat starch processing technology has the Martin method and the three horizontal snail method, the Martin method is through the washing machine will be separated from gluten and starch, starch slurry dewatering and drying, wet gluten drying to get gluten, three horizontal snail method is through the continuous washing machine will be separated from starch slurry and wet gluten, wet gluten drying to get gluten, starch slurry through the three horizontal snail starch slurry will be separated into AB starch and protein separation, and then the starch slurry dewatering drying

Martin method:

Separation by washing machine: firstly, the wheat flour slurry is fed into the washing machine. Inside the washer, the wheat flour slurry is agitated and mixed, which results in the separation of the starch granules from the gluten. Gluten is formed from the proteins in wheat, while starch is the other main ingredient.

Starch slurry dewatering and drying: Once the gluten and starch are separated, the starch slurry is fed into a dewatering device, usually a centrifuge. In the centrifuge, the starch granules are separated out and excess water is removed. The starch slurry is then fed into drying equipment, usually a starch air dryer, to remove the residual water until the starch becomes a dry powder.

Wet gluten drying: On the other hand, the separated gluten is fed into drying equipment, usually a gluten dryer, to remove the moisture and make gluten flour.

Three recumbent screw methods:

Continuous Washer Separation: similar to the Martin method, the wheat flour slurry is fed into a washer for processing. However, in this case, the washer may be a continuous process in which the wheat flour slurry flows continuously and is subjected to mechanical agitation to separate the starch from the gluten more efficiently.

Wet gluten drying: The separated wet gluten is fed into a gluten drying plant to remove moisture and make gluten.

Starch slurry separation: The starch slurry is fed into three decanter centrifuges. In this machine, the starch slurry is subjected to centrifugal force, which causes the starch particles to be deposited outwards, while proteins and other impurities remain inside. In this way, the starch slurry is separated into two parts: part A is the slurry containing starch, and part B is the protein liquid separated from the proteins in the starch slurry.

Dewatering and drying of starch slurry: The starch slurry in part A is fed into a dewatering plant for treatment to remove excess water. The starch slurry is then fed into drying equipment for drying until the starch becomes a dry powder.

These steps demonstrate the detailed process of the Martin method and the three-item recumbent screw method, from separating starch and gluten to dehydrating and drying the starch to obtain the finished products of wheat starch and gluten.

All rights reserved:Kaifeng Sida Agricultural Products Equipment Co.,L SitemapSitemappSitemapsupport:dian zi