Adr : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone : +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371-26630769

The sweet potato is one of the most versatile vegetables grown and enjoyed around the world. It can be roasted, baked, boiled, fried or steamed. The sweet potato root is also a good resource for starch extraction processing.

Sweet potato starch is used for many commercial purposes. In the food industry, the sweet potato starch will be used to make Asian noodles, sweeteners, beverages, citric acid and so on.

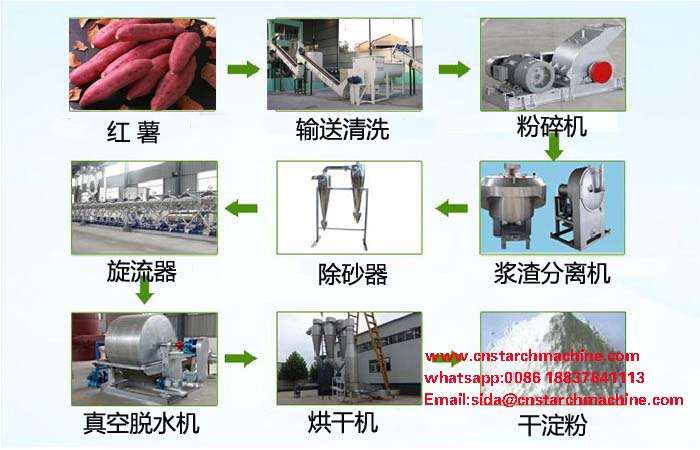

The processing of sweet potato into starch industrial production process description

1.Sweet potato cleaning and washing processing of sweet potato into starch

Coarsely cleaning of sweet potatoes takes place during the transport of sweet potatoes to the scrubber by channel. In addition, before the scrubber, straw and stones separators are installed. The main cleaning is conducted in scrubber (different kinds of high specialized machines are used). The remaining stones, sludge and light wastes are removed at this step. Water used for washing is then purified and recycled back into the process.

2.Sweet potato wet milling processing of sweet potato into starch

Most often the milling of sweet potato tubers is carried out by a hammer mill. The purpose of this stage is disruption of cell walls, which therefore release as much starch as possible to extract starch from sweet potato.

3.Starch extraction processing of sweet potato into starch

The sweet potato slurry will be pump to the starch extractor to separate the starch milk and the fiber with peels . Starch milk is contaminated by small fiber particles and the remaining components of the sweet potato juice–that’s why it is called raw starch milk.

4.Starch milk refining processing of sweet potato into starch

Raw starch milk is purified in the refining process. This involves the removal of small fibers from the starch milk and then the removal of juice water and starch milk condensation. For this purpose, the screens and hydro cyclones are commonly used. Hydro cyclones due to the low output are connected in parallel and works as multi-hydro cyclones. Refined starch milk has a density of about 22° Be, which is about 38% of starch.

5.Dewatering of refined starch milk process

Dewatering of refined starch milk is by a rotary vacuum filter to remove the excess water. After vacuum dewatering , the wet starch water content is around 38%.

6.Sweet potato starch drying process

The starch drying machine will dry the wet starch (with water content 36–40%) with hot air during 2–3 seconds. Then the starch is separated from hot air in cyclones. Due to short time of high temperature drying and intensive water evaporation from the starch granules, its surface is heated only around 40 °C. The starch will be dried at low temperature .

If you want to start processing of sweet potato into starch business and know more information about processing of sweet potato into starch machines , please contact with us freely .

All rights reserved:Kaifeng Sida Agricultural Products Equipment Co.,L SitemapSitemappSitemapsupport:dian zi