Adr : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone : +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371-26630769

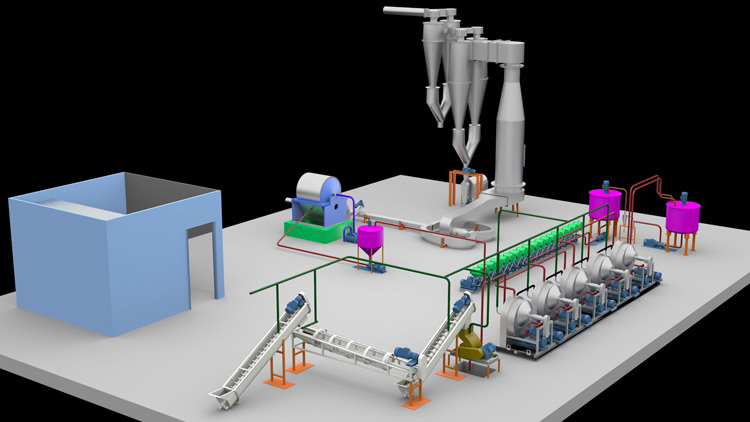

Fresh cassava tubers are processed during season and dry chips during the off-season in some countries. Extraction of flour from fresh cassava roots can be divided into five main stages: preparation (peeling and washing), rasping/crushing, purification (flour washing), dewatering and drying, and finishing (packaging).

Cassava flour is produced primarily by the wet milling of fresh cassava roots but in some countries such as Thailand it is produced from dry cassava chips. flour is the main constituent of cassava. About 20%~25% flour may be obtained from mature, good quality tubers. About 60 % flour may be obtained from dry cassava chips and about 10 % dry pulp may be obtained from cassava roots.

There is high demand for cassava flour in Nigeria. It is widely used in industries such as: textile, pharmaceuticals, oil drilling, paper and packaging, gum and adhesives, chemical and household products manufacturing, battery, drinks and beverages, foods and so on. The desire to conserve foreign exchange and reduce import dependency is the driving force for demand for cassava flour especially as regards its partial substitution for corn flour in user industries. The demand for cassava flour in Nigeria is in excess of 350,000 tons per annum. The current domestic production capacity to meet the estimated demand for cassava flour is less than 20 per cent. The current price/tonne (2013) of cassava flour ranges between N150, 000 – N180, 000

how to make cassava flour processing-cassava processing machine

All rights reserved:Kaifeng Sida Agricultural Products Equipment Co.,L SitemapSitemappSitemapsupport:dian zi