Adr : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone : +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371-26630769

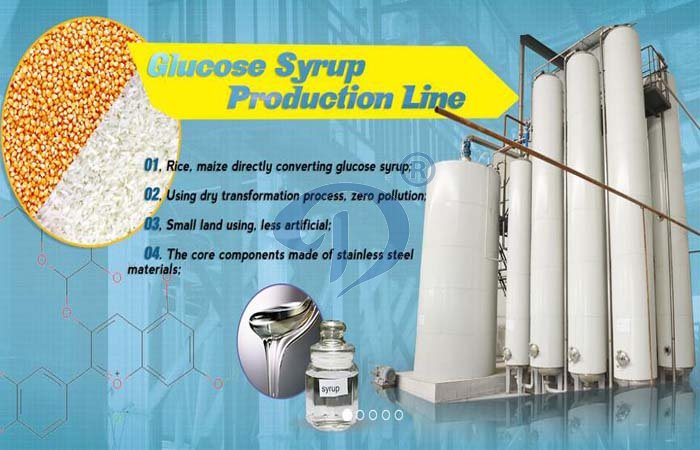

he description of Corn syrups production:

In the contemporary process, corn (maize) is milled to produce corn starch and an "acid-enzyme" process is used in which the corn starch solution is acidified to begin breaking up the existing carbohydrates, and then enzymes are added to further metabolize the starch and convert the resulting sugars to fructose.[18]:808–813 The first enzyme added is alpha-amylase which breaks the long chains down into shorter sugar chains – oligosaccharides. Glucoamylase is mixed in and converts them to glucose; the resulting solution is filtered to remove protein, then using activated carbon, and then demineralized using Ion-exchange resins. The purified solution is then run over immobilized xylose isomerase, which turns the sugars to ~50–52% glucose with some unconverted oligosaccharides, and 42% fructose (HFCS 42), and again demineralized and again purified using activated carbon. Some is processed into HFCS 90 by liquid chromatography, then mixed with HFCS 42 to form HFCS 55. The enzymes used in the process are made by microbial fermentation

Corn syrups, including HFCS, are made from corn starch. Commercial production of corn syrup began in 1864. In the late 1950s scientists at Clinton Corn Processing Company in Iowa tried to turn glucose from corn starch into fructose, but the process was not scalable. In 1965-1970 Yoshiyuki Takasaki, at the Japanese National Institute of Advanced Industrial Science and Technology (AIST) developed a heat-stable Xylose isomerase enzyme from yeast, and three years later AIST partnered with the Clinton company to commercialize the process.syrup manufacturing plant cost Please consult us.

All rights reserved:Kaifeng Sida Agricultural Products Equipment Co.,L SitemapSitemappSitemapsupport:dian zi