![]()

Adr : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone : +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371-26630769

processing capacity:20-100tons/24 hours

Application scope:Corn glucose Maltose Rice syrup

Product introduction: Syrup processing line,European craftsmanship Asian price,Welcome to consult the price

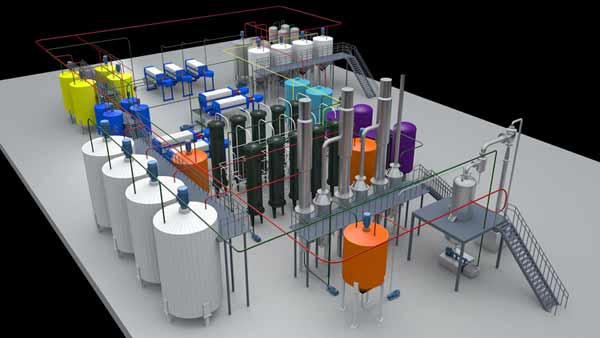

fructose syrup processing line 3D flow chart

During the high fructose corn syrup production ,The first enzyme added is alpha-amylase which breaks the long chains down into shorter sugar chains – oligosaccharides. Glucoamylase is mixed in and converts them to glucose; the resulting solution is filtered to remove protein, then using activated carbon, and then demineralized using Ion-exchange resins. The purified solution is then run over immobilized xylose isomerase, which turns the sugars to ~50–52% glucose with some unconverted oligosaccharides, and 42% fructose (HFCS 42), and again demineralized and again purified using activated carbon. Some is processed into HFCS 90 by liquid chromatography, then mixed with HFCS 42 to form HFCS 55.

our company are a professional starch syrup production machine supplier, specialized in manufacturing the syrup production machine, our high fructose syrup processing machine,glucose fructose syrup production machine,maltose syrup process machine capacity can be large and small, from 3-5tons per day to annual capacity 10 million tons, all is a complete set of syrup production machine, from raw material(usually starch or flour) handling to the final fructose syrup storage, fully automatic completed by our machine. The syrup production machine design and manufacturer like size, volume mainly according to the capacity demand, more details design requests about your syrup production machine, you can discuss with our engineer, then we can made machine for you as your requests.

Manufacturer by KaiFeng sida Company, about fructose syrup processing machine, we can offer:

1. Complete set energy saving syrup production equipment, according to client's different demands offer personal production plan, we will design the most ecnomic benefit and high efficiency technical plan for you.

2. Automatic control system: the advanced nature of control system is the guarantee of high quality products of syrup production. Continuous and stable production can reduce the production cost.

3. syrup production plant installation, adjust and operation training: all equipments through strict quality testing, after the test passes, Sida Company engineer will adjust the equipments and train the operation people, make sure the production technology reach the requests and your syrup production operation smoothly.

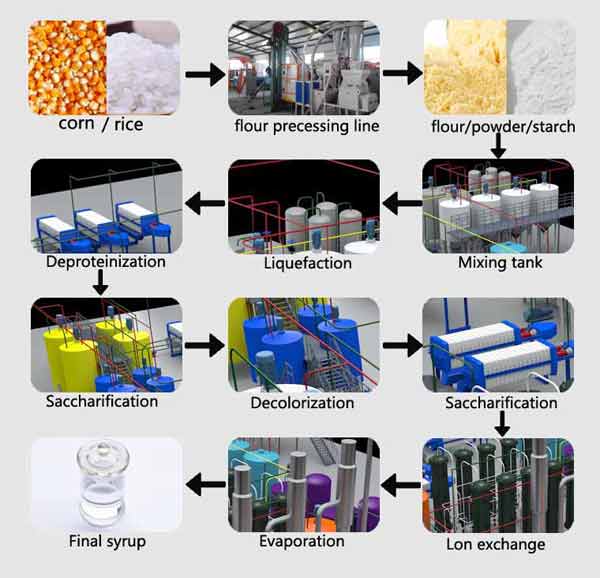

In the contemporary process, corn is milled to produce corn or rice Sorghum, potatoes and other grains flour or starch and an "acid-enzyme" process is used in which the flour or starch solution is acidified to begin breaking up the existing carbohydrates, and then enzymes are added to further metabolize the starch and convert glucose to fructose.

syrup processing line flow chart

The features of our company's high fructose corn syrup production is that we can use corn,rice,sorghum, potatoes and other grains as raw material to make high fructose syrup directly, no need to make starch.

High fructose or fructose syrup production detaills:

1. Mixing and liquefying process: mixing the corn flour / starch(or other raw material) with water, adjust the PH value to 5.0-6.0, after mixing add liquifying enzyme, equipped with ejector to complete the liquefaction process. Then we can get a suitable liquid can be prepared for glycosylated.

2. Saccharify: use saccharifying enzymes, processed the liquid temperature to 58-60 degree, after reach the request DE value can get into next process. Saccharify process performance decided the high fructose syrup production effect.

3. Liquid glucose decolorizing: uses second time decolorizing process to get bright syrup. This production process adopted plate and frame filter press machine to complete.

4. Filtration: this process adopt drum filter to remove soluble protein, decrease the protein content in glucose liquid.

5. Ion exchange system during high fructose syrup production: adjust the temperature and PH value, remove irons, salt and ash, get pure syrup.

6. Concentration: under vacuum condation to make heating and evaporation, make the syrup concentration meet the standards, after the temperature reduce, pump into next manufacturing process.

7. Isomerism process: this process function is change the glucose into fructose. More changed percentage, more sweetness.

8. High fructose syrup refining process: the isomerized raw syrup was prepared by the secondary decoloration and the secondary concentration process. After adjusting the temperature, it was pumped into the special tank for storage, which was the finished product F42 high fructose syrup.

Above all, this is our Company high fructose syrup production, the main equipments is: high temperature ejector, ion exchange column, tanks, evaporator, filter press.

syrup production machine ,Be praised by European merchants

Our completed projects in Europe、America 、Africa Nigeria, Malaysia、Tanzania, you can be visited.If you need corn&rice syrup processing machine、fructose syrup processing machine、Maltose Syrup Processing machine、 Glucose Syrup Processing machine、starch and flour processing machine and other problems,Please leave a message under the website,Or send email:sida@cnstarchmachine.com, or consult our online customer service. We will answer your questions immediately. Welcome to the consultation.

Add : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone : +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371--26630769

All rights reserved:Kaifeng Sida Agricultural Products Equipment Co.,L SitemapSitemappSitemapsupport:dian zi