![]()

Adr : Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone : +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371-26630769

processing capacity:10-300 tons/24 hours

Application scope:Starch production of yam

Product introduction: Complete set starch processing line,European craftsmanship Asian price,Welcome to consult the price

yam starch processing line

Advantage of yam starch processing line

1. Good performance; high efficiency

2. Stainless steel construction

3. High level machining, equipment manufacturing excellence

4. Good supervision, commissioning and assistance

5. Low maintenance, simple operation

6. Pumps, motors, piping and instrumentation installed on the same integrated frame

7. Closed system, easy to clean and CIP

8. Fully communicate with the user to provide the best engineering design and facility layout

yam Starch Production Process:

Fresh yam → yam washing → Peeling → Grinding → Centrifuge sieve → Desanding → Hydrocyclone → Dewatering → Drying

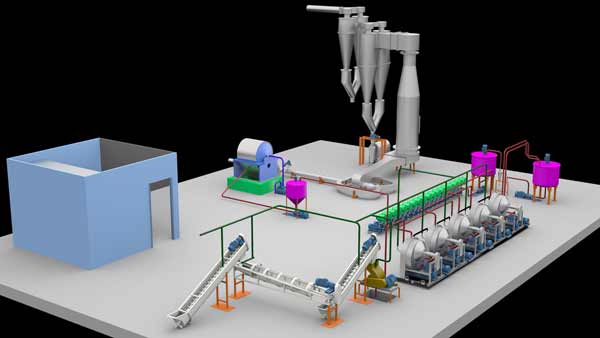

yam starch production machine flow process chart

Main process of yam starch production line:

1. yam peeling and washing section for yam starch production line:The purpose of this unit is to get rid of sandstone, clay of yam, and to deposit cleaned yam in the yam temporary hopper.

yam cleaning and peeling machine

2. Crushing section during the yam starch production line: The crushing unit is the most important step for extracting yam starch. Highly-efficient crushing machine will release the starch in yam at most.

yam crushing mill machine(yam grating machine)

3. Centrifugal extracting section during the yam starch production line:The yam starch slurry and residue will be separated from the starch milk.

4. Desanding section during the yam starch production line: Removing the sand in the starch slurry.

5. Concentration and refining section during the yam starch production line:Working through the hydroclone, there are 2 steps, including concentration and refining so that we can get purier starch slurry.

Starch refining hydrocyclone

6. Vacuum dewatering section during the yam starch production line: The starch slurry is pumped into inlet tank of vacuum dewatering machine. Then the vacuum rotary drum will adsorb the starch on the drum surface and the filtrate is transferred out of the system by filtrate pump. The filter cake on the drum will be peeled off by peeler and then transferred to the air dryer by screw conveyor.

yam starch dryer machine

7. Air-stream drying section during the y starch yam production line: After dewatering process, the air dryer will dry the starch to the required moisture of the commercial starch.

Above all steps are the whole line for yam starch production.We can provide you the complete yam starch production machine and we have exported many sets yam starch processing machine to Africa countries.

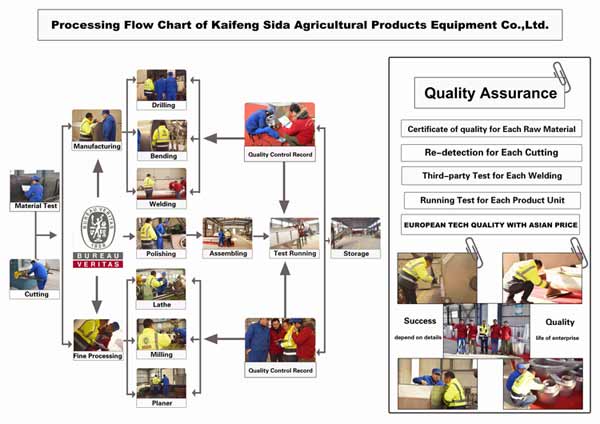

Our processing machines are fully tested by BVI Bureau Veritas in France and 100% of the processing technology is up to standard.

Bureau Veritas is the industry promoter of testing, inspection and certification services. By providing quality services, BVI helps customers cope with increasing challenges in terms of quality, health, safety, environmental protection and social responsibility.

As a trusted business partner, Biwei provides innovative solutions that not only help customers meet the requirements of regulations and standards, but also reduce risks, improve performance and promote their sustainable development.

The starch processing line manufacturing process of Kaifeng Sida company has got praise from European customers.

Our completed projects in Malaysia、 Europe、America 、Africa Nigeria, Tanzania, you can be visited.If you have cassava、 potatoes、 sweet potato、 corn 、plantain 、yam processing starch and flour processing, corn&rice syrup processing machine and other problems,Please leave a message under the website,Or send email:sida@cnstarchmachine.com, or consult our online customer service. We will answer your questions immediately. Welcome to the consultation.The Company manager go to Nigeria or your country, you can to talk with manager.

Around our machines all over the world have completed project can visit, our machines with the third party inspection agency France Bureau Veritas and 100% high quality qualified, machine quality, advanced technology, perfect service quality, Now order the machine and we will give you the best price.

Strict quality inspection system, mature management and after-sale service for your technical support

Add: Huanglong garden in Kaifeng Economic Development Zone, Henan

Phone /whatapp: +86 18438491113

Email : sida@cnstarchmachine.com

Tel : +86 371--26630769

Aerial view of the factory

Kaifeng Sida Agricultural Products Equipment Co., Ltd is established in 1994, possessing the registered assets of RMB36 million, covering an area of 333335 square meters.

Our company own 15pcs national invention patents and pass the ISO9001 certificate (the international quality management system), BV certificate, and own the European welder certificate.

Our company is specialized in manufacturing various processing equipment of starch and flour. The raw materials can be cassava, potato, sweet potato, etc. In domestic market, our company first use the technology to convert corn/maize, rice and broken rice directly to glucose syrup, fructose syrup and maltose syrup.

Our machines have been exported to many foreign countries, such as The United States, France, Britain, Australia, South Africa, Nigeria, India, Bulgaria, Russia, Indonesia, etc. And our equipment always get the high reputation from our clients.

All rights reserved:Kaifeng Sida Agricultural Products Equipment Co.,L SitemapSitemappSitemapsupport:dian zi